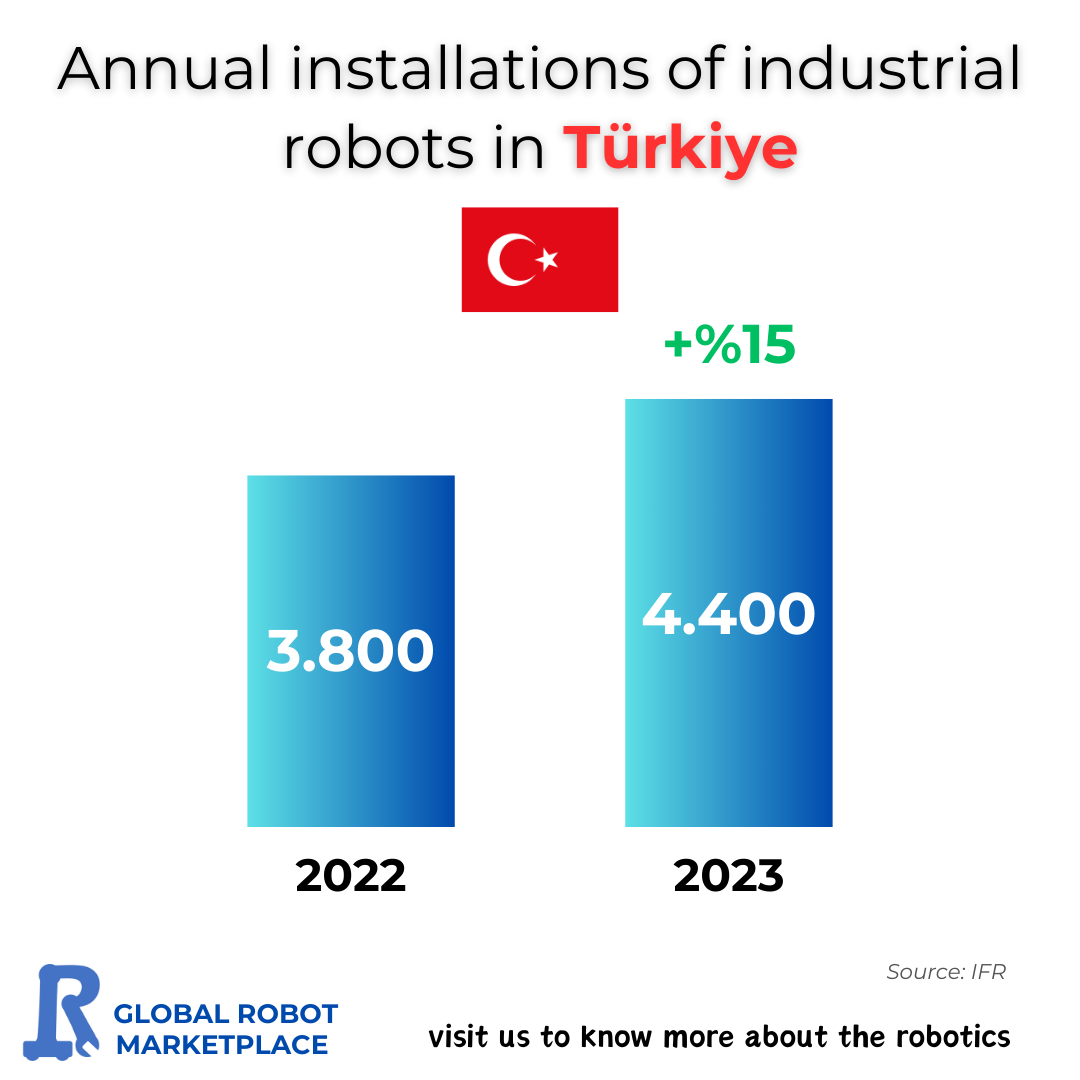

The industrial robot sector is experiencing significant growth globally, with Türkiye emerging as a key player in this transformation. According to recent data, the annual installation of industrial robots in Türkiye witnessed a remarkable increase of 15% between 2022 and 2023. The figures, as reported by the International Federation of Robotics (IFR), indicate an increase from 3,800 installations in 2022 to 4,400 in 2023. This trend reflects the growing importance of automation across various sectors in Türkiye.

Key Drivers of Growth

Manufacturing Boom

Türkiye's manufacturing sector has been at the forefront of this automation surge. As global demand for efficient and scalable production systems increases, industries such as automotive, electronics, and textiles in Türkiye are adopting robotics to enhance productivity and maintain competitiveness.Government Support

The Turkish government has been actively supporting technological advancements through incentives and strategic investments in industrial automation. Initiatives to strengthen domestic robotics manufacturing and integrate robotics into education and R&D are creating a robust ecosystem for the industry.Economic Resilience

Despite global economic uncertainties, Türkiye has displayed resilience by focusing on technological adoption. Robotics is increasingly seen as a solution to labor shortages and rising operational costs, providing industries with the tools to adapt to modern challenges.

Impact on Key Sectors

Automotive Industry

Türkiye, a major hub for automotive production, is leveraging industrial robots to streamline assembly lines and increase production efficiency. Robots are being used for welding, painting, and material handling, ensuring precision and consistency in manufacturing processes.Electronics Manufacturing

The growing consumer electronics market in Türkiye has driven demand for robots capable of assembling delicate components with high precision. Robotics ensures quality and reduces the margin for error, enabling local manufacturers to meet global standards.Food and Beverage Industry

Automation in food processing and packaging is gaining traction in Türkiye. Robots are helping industries handle repetitive tasks, maintain hygiene standards, and enhance throughput, especially in export-oriented businesses.

Challenges to Address

Despite the impressive growth, several challenges remain:

Skill Gap

The rapid adoption of robotics necessitates a workforce trained in programming, operating, and maintaining advanced robotic systems. Bridging this skill gap is essential for sustaining long-term growth.Cost of Adoption

For small and medium-sized enterprises (SMEs), the upfront cost of deploying industrial robots can be prohibitive. Policies to provide financial assistance or leasing options could help democratize access to automation.Dependence on Imports

A significant portion of the robots installed in Türkiye is imported. Enhancing local production capabilities could reduce costs and dependency on foreign suppliers.

Future Outlook

The upward trend in robot installations in Türkiye is expected to continue as industries increasingly embrace automation. With advancements in artificial intelligence, machine learning, and Internet of Things (IoT) technologies, the capabilities of industrial robots are set to expand further.

Türkiye's strategic location, skilled workforce, and government support position it as a promising hub for industrial automation in the region. Projections suggest that the industrial robotics market in Türkiye will grow not only in terms of installations but also in innovation and development, contributing significantly to the global automation landscape.

Conclusion

The 15% increase in robot installations from 2022 to 2023 is a testament to Türkiye's commitment to modernization and technological advancement. As industries across the country continue to adopt robotics to boost efficiency, productivity, and competitiveness, Türkiye is poised to become a leader in industrial automation within its region and beyond. Collaboration between government, academia, and industry stakeholders will be crucial in ensuring the sustainable growth of this sector.

This growth story highlights how automation, when strategically implemented, can drive economic transformation and unlock new opportunities for businesses and the workforce alike.