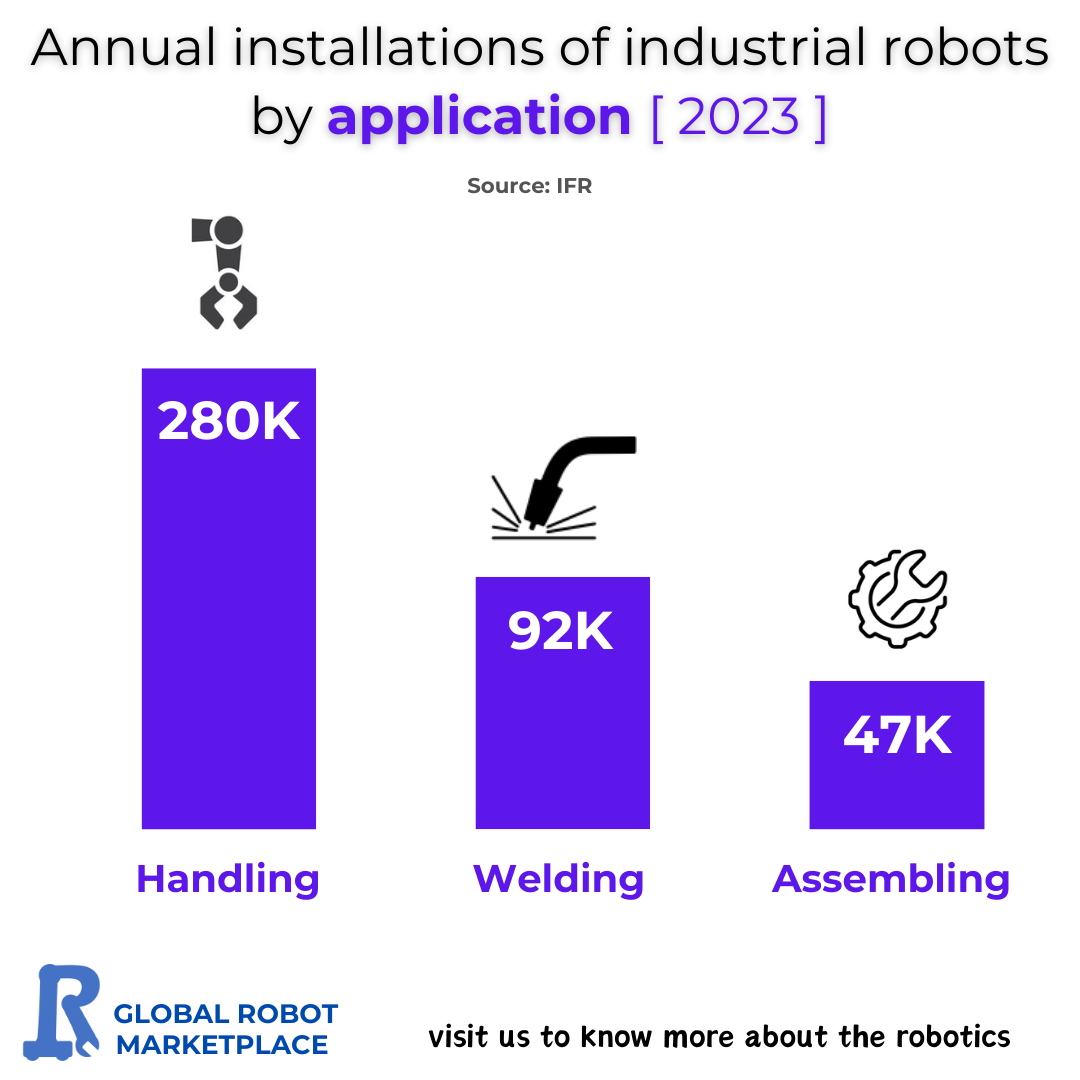

Industrial robots have become a cornerstone of modern manufacturing, helping industries increase efficiency, reduce costs, and improve safety. According to the International Federation of Robotics (IFR), the year 2023 saw remarkable growth in the installation of industrial robots across various sectors, with significant investments focused on three primary applications: handling, welding, and assembling. This article delves into the details of these applications, the reasons behind their popularity, and the potential future impact of industrial robotics.

Industrial Robot Application Trends

1. Handling Robots – 280,000 Installations

Handling robots, with 280,000 installations, dominated the industrial robot market in 2023. These robots are designed to manipulate objects with precision and speed, performing tasks such as loading, unloading, sorting, and packaging. Handling robots are widely adopted in industries like logistics, automotive, electronics, and food and beverage, where they streamline workflows, reduce human error, and optimize productivity.

The high demand for handling robots can be attributed to the increasing need for automated material handling solutions in e-commerce and manufacturing. As companies strive to meet growing consumer demand and manage supply chain complexities, handling robots have proven to be indispensable in maintaining high throughput.

2. Welding Robots – 92,000 Installations

Welding robots are crucial in sectors such as automotive and heavy machinery, where precise and repeatable welding processes are essential for product quality and durability. In 2023, the industry installed 92,000 welding robots, underscoring their importance in automating tasks that require accuracy and high-temperature handling.

Welding is a physically demanding and hazardous job. By deploying robots, manufacturers protect workers from harmful fumes, burns, and repetitive stress injuries. Furthermore, welding robots contribute to consistent product quality, reduce waste, and increase production rates, making them a preferred solution for many manufacturers.

3. Assembling Robots – 47,000 Installations

Assembling robots, with 47,000 installations in 2023, play a vital role in the manufacturing sector by automating complex assembly processes. These robots are especially valuable in the electronics, automotive, and aerospace industries, where precision assembly is critical to product function and safety.

Assembling robots are designed to handle delicate and small components, assemble intricate parts, and ensure high levels of accuracy. They enable manufacturers to maintain consistent quality, reduce assembly errors, and increase output. As more industries adopt automation, the demand for assembly robots is expected to grow.

The Future of Industrial Robotics

The growth of industrial robots reflects the global push for automation, driven by factors such as labor shortages, increasing production demands, and the need for high-quality manufacturing standards. With advancements in artificial intelligence and machine learning, robots are becoming smarter, more adaptable, and capable of taking on even more complex tasks.

In the near future, we can expect industrial robots to become increasingly collaborative, working alongside human employees to enhance productivity. This shift, known as "cobotics," could transform workplaces by combining the strengths of human creativity and robotic precision.

Conclusion

The 2023 report on industrial robot installations reveals the significant impact of robotics in handling, welding, and assembling applications. With continuous innovation, industrial robots will likely expand their role in manufacturing, offering exciting possibilities for efficiency and productivity improvements. For those interested in learning more about robotics and the latest trends in automation, the Global Robot Marketplace offers insights into how these technologies are shaping the future of industries worldwide.