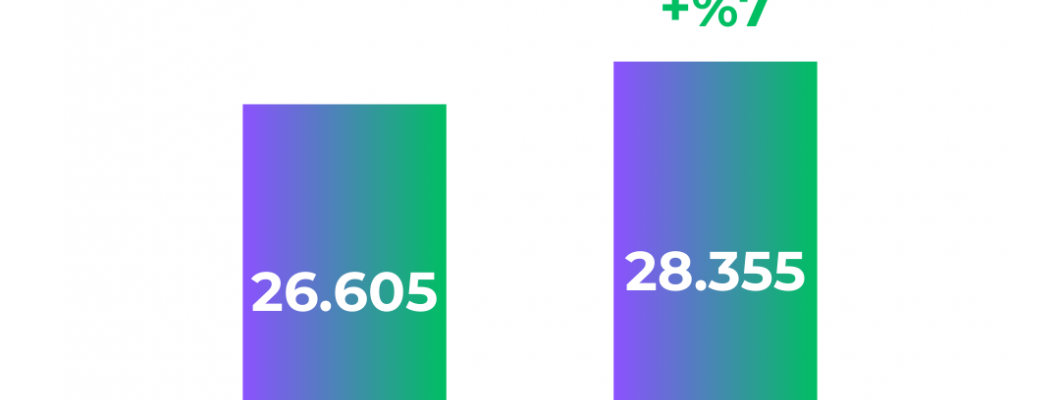

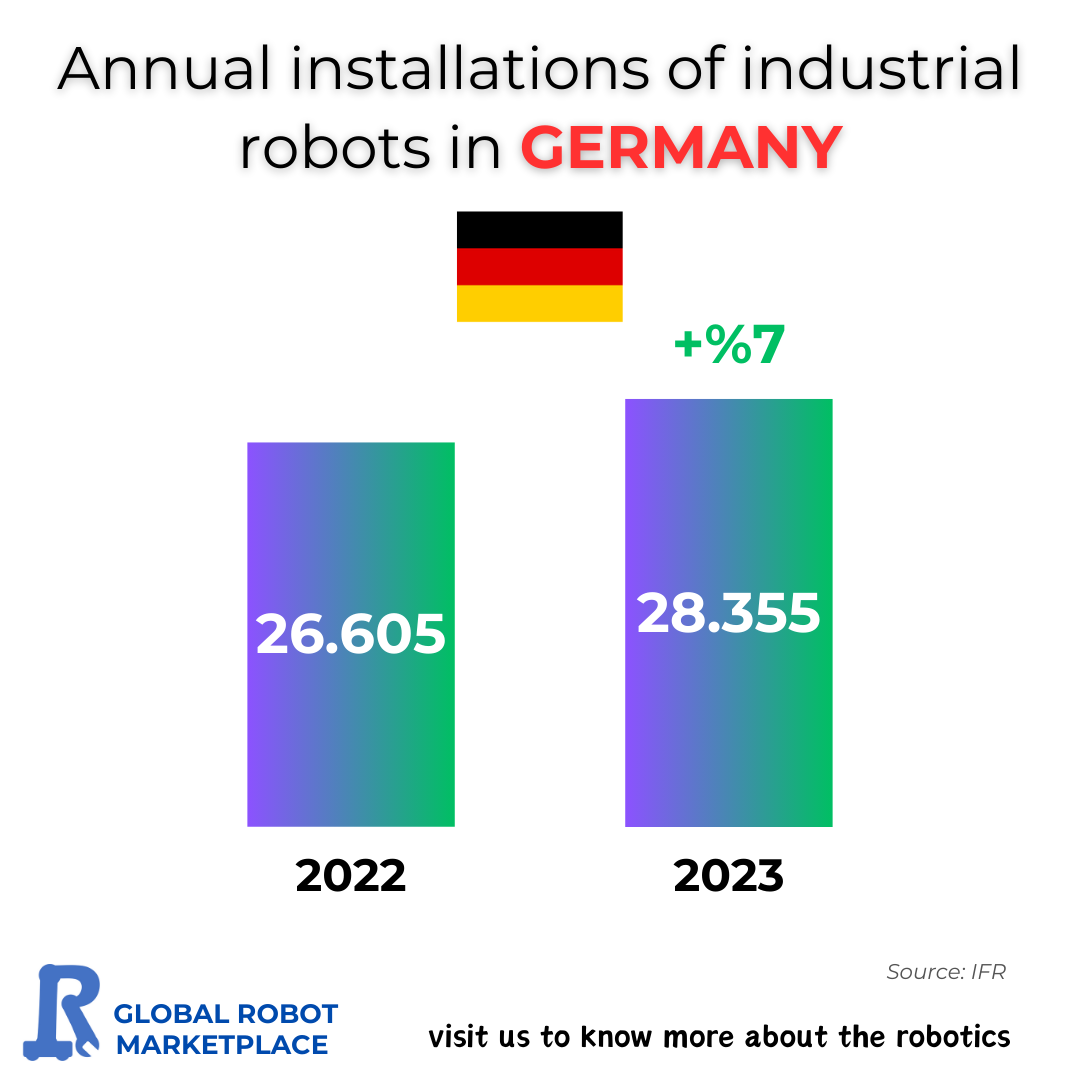

The landscape of industrial automation is evolving rapidly, and Germany a global powerhouse in manufacturing continues to play a significant role in this transformation. According to the recent data from the International Federation of Robotics (IFR), Germany witnessed a notable 7% increase in industrial robot installations in 2023 compared to the previous year. This growth, rising from 26,605 units in 2022 to 28,355 units in 2023, reflects the country's commitment to leveraging robotics to boost productivity, efficiency, and competitiveness.

Why Industrial Robots Matter

Industrial robots are at the heart of modern manufacturing processes, offering unmatched precision, reliability, and scalability. From automotive assembly lines to electronic manufacturing and packaging industries, these robots streamline operations by performing tasks such as welding, painting, material handling, and inspection.

Germany's robust manufacturing sector, often dubbed the "engine of Europe," is highly dependent on automation technologies to maintain its leadership in global markets. In this context, the steady rise in robot installations is a strong indicator of the country's readiness to embrace Industry 4.0—a vision for smart, automated, and interconnected production systems.

Growth of Industrial Robot Installations in Germany: A Deep Dive into 2023 Trends

The landscape of industrial automation is evolving rapidly, and Germany—a global powerhouse in manufacturing—continues to play a significant role in this transformation. According to the recent data from the International Federation of Robotics (IFR), Germany witnessed a notable 7% increase in industrial robot installations in 2023 compared to the previous year. This growth, rising from 26,605 units in 2022 to 28,355 units in 2023, reflects the country's commitment to leveraging robotics to boost productivity, efficiency, and competitiveness.

Why Industrial Robots Matter

Industrial robots are at the heart of modern manufacturing processes, offering unmatched precision, reliability, and scalability. From automotive assembly lines to electronic manufacturing and packaging industries, these robots streamline operations by performing tasks such as welding, painting, material handling, and inspection.

Germany's robust manufacturing sector, often dubbed the "engine of Europe," is highly dependent on automation technologies to maintain its leadership in global markets. In this context, the steady rise in robot installations is a strong indicator of the country's readiness to embrace Industry 4.0—a vision for smart, automated, and interconnected production systems.

Breaking Down the 2023 Surge

1. Economic Resilience and Automation

Germany has demonstrated resilience in overcoming global challenges like supply chain disruptions and labor shortages. Companies increasingly turn to robots to mitigate these issues, ensuring consistent production levels and reducing dependency on human labor for repetitive tasks.

2. Sectoral Trends

The automotive sector continues to be the leading adopter of industrial robots, especially as it transitions toward electric vehicles (EVs). EV production often involves specialized processes, such as battery assembly, which require precision beyond human capability. Other sectors, including food processing, pharmaceuticals, and logistics, have also seen increased robotic adoption.

3. Government Support

Germany's government has played a pivotal role in fostering innovation and supporting the adoption of robotics and AI. Subsidies for adopting advanced manufacturing technologies, as well as research grants for robotics, have incentivized businesses to modernize their operations.

The Role of Emerging Technologies

The integration of artificial intelligence (AI) and machine learning with robotics is another driving force behind the surge in installations. AI-enabled robots can now adapt to dynamic environments, learn from data, and perform complex tasks, making them more attractive to a broader range of industries. Additionally, advancements in sensor technology and cloud computing have enhanced the performance and affordability of industrial robots.

Germany's Place in the Global Context

Germany ranks among the world's top countries for industrial robot density (robots per 10,000 workers), alongside nations like South Korea and Japan. This high density underscores the country’s deep integration of robotics into its workforce.

The 7% growth in installations in 2023 aligns with global trends, where industries worldwide are accelerating automation adoption. Notably, as international competition intensifies, staying ahead in automation helps Germany maintain its position as a global manufacturing hub.

Challenges Ahead

Despite the positive trends, Germany’s robotics journey is not without hurdles. The rising cost of advanced robotics systems, coupled with concerns about workforce displacement, presents challenges. Additionally, small and medium-sized enterprises (SMEs), which form the backbone of Germany’s economy, often face barriers to adopting robotics due to cost and complexity.

Addressing these issues requires continued investment in affordable robotics solutions, workforce upskilling programs, and collaborative robots (cobots) designed for smaller-scale operations.

Looking to the Future

The future of robotics in Germany looks promising. The increasing use of collaborative robots, advances in AI integration, and the push for sustainable manufacturing will likely drive further growth in the years ahead. Germany's commitment to innovation and its proactive policies in technology adoption position it well to lead the next wave of industrial automation.

As the world moves closer to an era dominated by smart factories, Germany's progress in robotics serves as a blueprint for other nations. The consistent growth in robot installations highlights not only the technological strides being made but also the strategic importance of automation in shaping the future of manufacturing.