09 Jul 2024

0 Comment(s)

721 View(s)

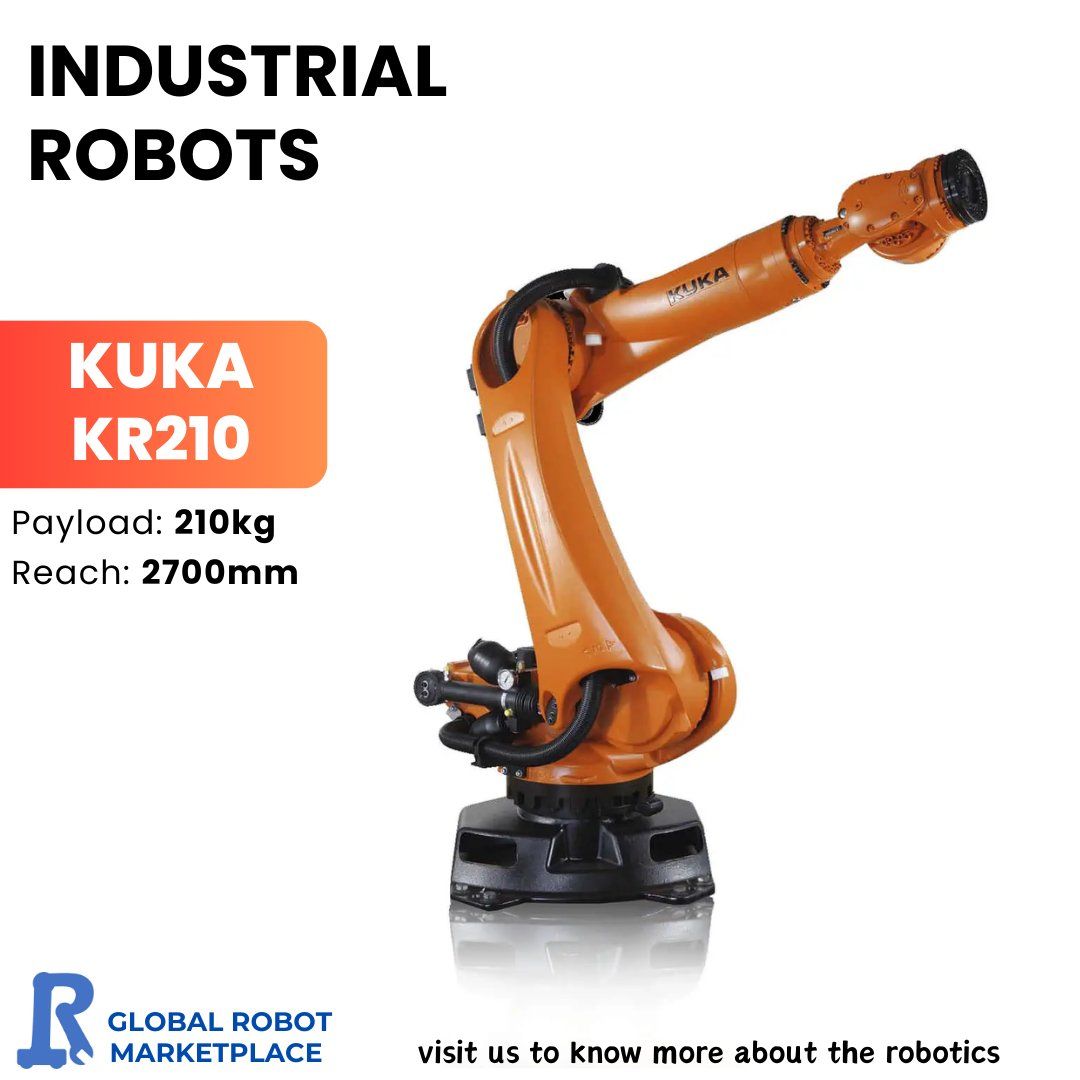

The KUKA KR 210 is part of KUKA's line of industrial robots, known for their versatility, precision, and durability. Here's an overview of the KUKA KR 210:

Specifications:

- Payload: 210 kg (462 lbs)

- Reach: Approximately 2,700 mm (106.3 inches)

- Axes: 6-axis robot

- Repeatability: ±0.06 mm

- Mounting: Floor or ceiling

Features:

- High Payload Capacity: Capable of handling up to 210 kg, suitable for heavy-duty applications.

- Extended Reach: Its long reach allows it to perform tasks over a wide area, ideal for applications requiring extensive coverage.

- Versatility: The 6-axis design offers a high degree of flexibility, enabling it to execute complex and varied tasks.

- Precision: High repeatability ensures reliable and accurate operations, crucial for tasks demanding high precision.

- Durability: Built to withstand tough industrial environments, ensuring consistent performance over time.

Applications:

- Material Handling: Efficiently moves materials in manufacturing processes.

- Assembly: Assists in assembling components in automotive, electronics, and other industries.

- Palletizing: Stacks and organizes products onto pallets.

- Welding: Performs welding tasks with high precision.

- Machine Tending: Loads and unloads parts from machines.

- Packaging: Assists in the packaging of products.

Benefits:

- Increased Productivity: Automates repetitive and labor-intensive tasks, leading to higher throughput.

- Improved Safety: Reduces the need for human intervention in potentially hazardous tasks.

- Enhanced Quality: Consistent and precise operations improve product quality.

- Cost Efficiency: Reduces labor costs and minimizes downtime with reliable performance.

Variants:

The KR 210 comes in different variants designed for specific applications, such as:

- KR 210 R2700 prime: Optimized for reach and payload capacity.

- KR 210 R3100: Offers an even longer reach for applications requiring extensive range.