South Korea remains at the forefront of global robotics adoption, consistently recognized as one of the most automated nations in the world. With its cutting-edge manufacturing sector and emphasis on innovation, the country has been a leader in integrating robotics to drive industrial efficiency and competitiveness. However, recent data from the International Federation of Robotics (IFR) highlights a slight dip in the annual installation of industrial robots in 2023, prompting questions about the underlying factors and potential implications for the robotics landscape.

Key Figures and Trends

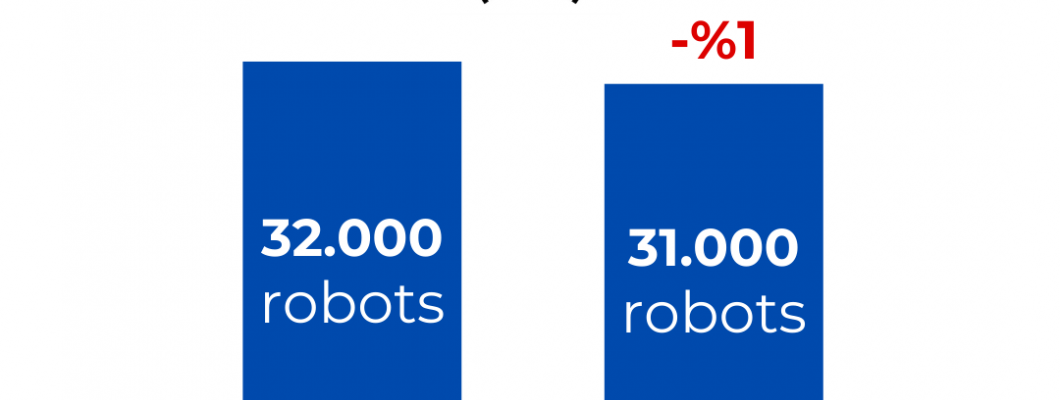

In 2022, South Korea installed 32,000 industrial robots, underscoring its robust commitment to automation. This figure marked another milestone in the nation’s continuous growth in robotics implementation across industries such as automotive, electronics, and manufacturing. However, 2023 witnessed a modest decrease, with 31,000 robots installed a 1% decline compared to the previous year.

While this reduction might appear insignificant at first glance, it represents a break in the steady growth trajectory South Korea has experienced in recent years. Given the country’s position as a global robotics leader, even slight changes in its automation trends provide valuable insights into the broader dynamics of industrial robotics adoption worldwide.

Understanding the Decline

The 1% drop in installations may stem from a combination of factors, including:

Economic Headwinds: Global economic challenges, including inflation, supply chain disruptions, and geopolitical tensions, have created an environment of caution for businesses. Many companies may have postponed investments in new robotics systems in favor of optimizing existing operations.

Market Saturation: South Korea boasts one of the highest robot densities globally, with hundreds of robots per 10,000 employees in manufacturing. In such a highly automated environment, the pace of new installations may naturally slow as industries reach optimal levels of automation.

Technological Shifts: The robotics industry is rapidly evolving, with a growing emphasis on collaborative robots (cobots), artificial intelligence, and software-driven solutions. Businesses may be focusing on upgrading existing robots with advanced capabilities rather than investing in entirely new units.

Government Policy and Industry Focus: Policy shifts or changes in funding priorities could also play a role. For example, increased attention to research and development (R&D) in next-generation robotics might divert resources from large-scale installations.

Sectoral Impact

Different sectors within South Korea’s economy may be experiencing varying trends in robotics adoption:

Automotive: The automotive industry, a traditional driver of robot installations, may be focusing more on electric vehicle (EV) production and battery technologies, potentially reallocating investments away from general automation.

Electronics: The demand for robots in electronics manufacturing remains high, driven by the need for precision and scalability. However, global semiconductor shortages and fluctuating consumer demand could have tempered growth in this sector.

Small and Medium Enterprises (SMEs): South Korea has been encouraging SMEs to adopt robotics through subsidies and training programs. While progress is evident, SMEs might face budgetary constraints, impacting the pace of installations.

The Bigger Picture

Despite the slight decline, South Korea’s robotics sector remains a global powerhouse. The country’s high level of robot density demonstrates the advanced stage of its industrial automation efforts. Moreover, South Korea’s commitment to smart factories and Industry 4.0 initiatives ensures that its industries continue to evolve and remain competitive in a rapidly changing global market.

The focus is shifting toward more sophisticated applications of robotics, including:

Collaborative Robots (Cobots): Designed to work alongside humans, cobots are gaining traction for their flexibility and cost-efficiency, particularly in industries requiring high customization.

AI and Machine Learning Integration: Robotics systems with AI capabilities are enabling smarter, more adaptive automation solutions.

Service Robots: Beyond traditional industrial settings, South Korea is also investing heavily in service robots for healthcare, logistics, and domestic applications.

Future Outlook

The minor reduction in industrial robot installations in 2023 should be seen as a momentary adjustment rather than a long-term trend. South Korea’s strategic focus on automation, supported by strong government policies and private sector innovation, positions it to maintain its leadership in the global robotics arena.

Looking ahead, several factors are likely to influence the trajectory of robotics adoption:

Global Economic Recovery: As economic conditions stabilize, industries are expected to resume investments in automation at an accelerated pace.

Technological Advancements: Continued breakthroughs in robotics, AI, and IoT will drive demand for more advanced systems.

Export Opportunities: South Korea’s robotics manufacturers are well-positioned to capitalize on growing demand in emerging markets, further boosting the sector.

South Korea’s slight dip in robot installations in 2023 does not diminish its status as a leader in industrial automation. On the contrary, it highlights the dynamic nature of the robotics industry, where economic, technological, and market forces are constantly reshaping the landscape. As industries worldwide increasingly rely on robotics to enhance productivity and resilience, South Korea’s experience offers valuable lessons and inspiration for the future of automation.