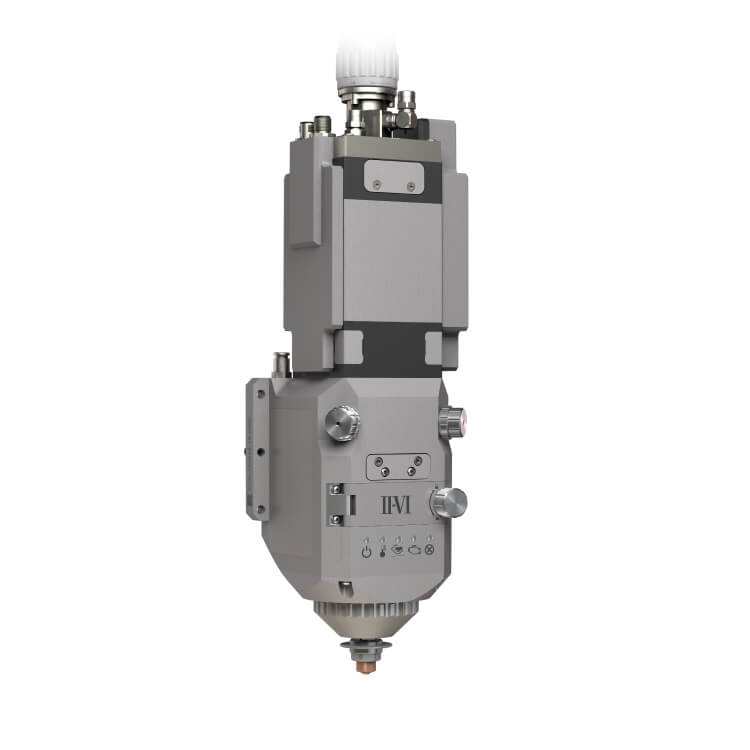

HIGHYAG BIMO-FSC3 Laser Cutting Head

Open your store for free → Become a Seller

II-VI’s third-generation cutting heads meet all requirements for flat sheet laser cutting: productivity, reliability, and connectivity.

The optomechanical system has been designed for extreme high powers and 24/7 operation in industrial environments. Our even faster, new zoom optics, with its extended and infinitely variable adjustment of focus diameter (M) and focus position (Z), enables outstanding cutting performance over a wide range of materials and thicknesses, leading to maximum flexibility and productivity. New features prevent contamination to ensure high reliability. Integrated sensors offer a superior level of embedded intelligence, providing condition monitoring and maximizing uptime. Welcome to the new generation of MZ laser cutting heads.

Intelligent flat sheet laser cutting system

- Motorized, fully independent adjustment of focus position (Z) and diameter (M)

- Integrated status and monitoring sensors

https://ii-vi.com/product/laser-processing-head-bimo-fsc-new-generation/

Features

- Suitable for up to 15 kW laser power (100% duty cycle)

- Autofocus system

- Rugged capacitive height sensing

- Contamination-proof optomechanical design with certified IP65 rating if a II-VI fiber cable is used

- Minimized laser-power-induced focus shift for best cutting quality

- Three cover slides for maximum protection of optics

- Motorized, fast, and yet independent adjustment of magnification (M) and focal-plane positions (Z)

- Typical M- and Z-ranges:

– M = 1.25 to 3.8 @ Z = 0 mm

– Z = -30 mm to +15 mm (extended Z-range option available)

– Focusing length configurable - Available interfaces: Profinet, EtherCAT, and Ethernet IP

Applications

- Thin and thick sheet cutting for all metal types such as steel, aluminum, brass, and copper

- The cutting heads’ volume claim enables bevel cutting with high-brightness fiber, disc, or diode lasers (NA = 0.125) to a tilting angle of 45°