- Stock: 200

- Brand: HONPINE

- Model: FMC05213-0015

text_write_alogin |

We’ll get back to you shortly.

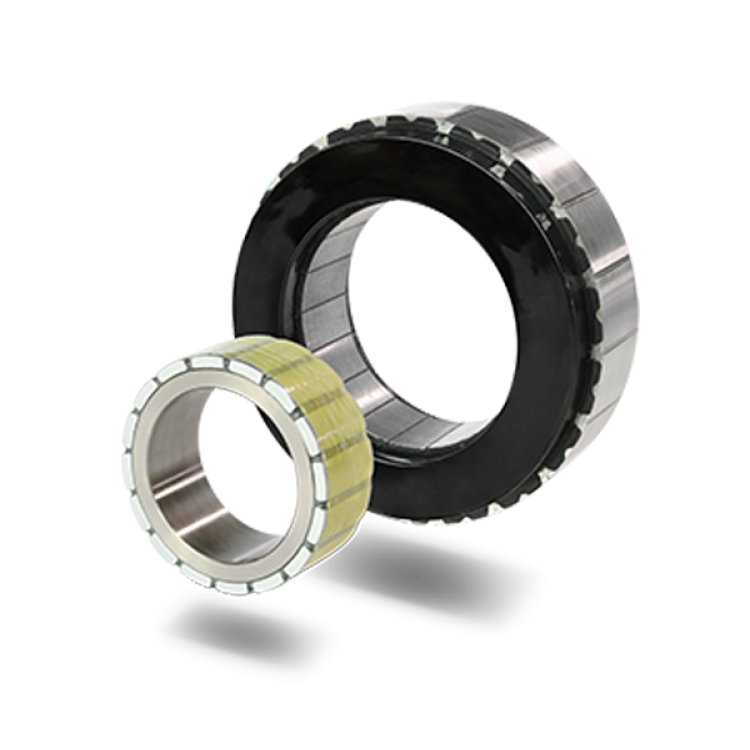

The internal rotor frameless torque motor is a specialized type of permanent magnet synchronous motor (PMSM) composed of two core components: the rotor and stator. The rotor is internally positioned, while the stator is externally mounted. Its innovative design eliminates traditional motor housings, bearings, and shafts, retaining only the rotor and stator assemblies. The rotor typically adopts a ring-shaped structure integrated with permanent magnets, directly mounted on the load shaft. The stator consists of copper windings and laminations, generating electromagnetic forces to drive rotor rotation. This configuration achieves torque output through efficient magnetic field interaction, making it ideal for high-precision applications such as robotic joints and industrial automation. It enables direct load driving, minimizing mechanical transmission losses.

Features

Removes traditional housings and frames, reducing volume by approximately 30%-50% and significantly lowering weight. Ideal for space-constrained, integrated systems.

● High Power Density and Torque Output

Utilizes multi-pole and multi-slot designs with optimized permanent magnet arrangements, enhancing torque density by 20%-40% to deliver greater torque per unit volume.

Reduces iron and copper losses, improving efficiency by 10%-15% compared to conventional motors.

● Efficient Heat Dissipation and Low Thermal Loss

Employs vacuum potting technology combined with high thermal conductivity materials, boosting heat dissipation efficiency. Temperature rise is reduced by 15%-25%, extending operational lifespan.

● High Dynamic Response and Precision

Directly drives loads, eliminating backlash from gears/belts. Response speed increases by over 30%, achieving micrometer-level positioning accuracy.

● Quiet Operation and Low Maintenance

Eliminates mechanical transmission noise, operating at sound pressure levels below 50dB. Simplified structure reduces wear-prone components, lowering maintenance frequency by 60%-80%.

● Customizable Integration Flexibility

Supports parameter customization (rotor/stator dimensions, magnetic waveforms) for seamless integration into robotic joints, medical devices, or other systems, adapting to diverse design requirements.