The use of robots in assembling applications has become increasingly popular in recent years, with advancements in technology and automation making it possible to improve efficiency, reduce costs and improve quality. Robotic assembly has many benefits, including the ability to perform tasks that are repetitive, dangerous or difficult for humans to perform. In this article, we will discuss the use of robots in assembling applications, their advantages, and the different types of robots used in the assembly process.

Robotic assembly involves the use of robots to perform tasks such as assembling parts, welding, painting, and packaging. These robots are programmed to perform specific tasks and are often equipped with sensors that allow them to detect and adjust to changes in the environment. The use of robots in the assembly process offers several advantages over traditional assembly methods.

One of the main advantages of using robots in assembly applications is increased efficiency. Robots are able to perform tasks at a much faster rate than humans, which can lead to faster production times and increased productivity. Robots are also able to work around the clock without the need for breaks or rest, which further increases their efficiency.

Another advantage of using robots in assembly applications is improved quality. Robots are programmed to perform tasks with a high degree of accuracy and precision, which can help to reduce errors and improve the overall quality of the product. Robots are also able to perform tasks that require a high level of consistency, which can further improve quality by ensuring that each product is identical.

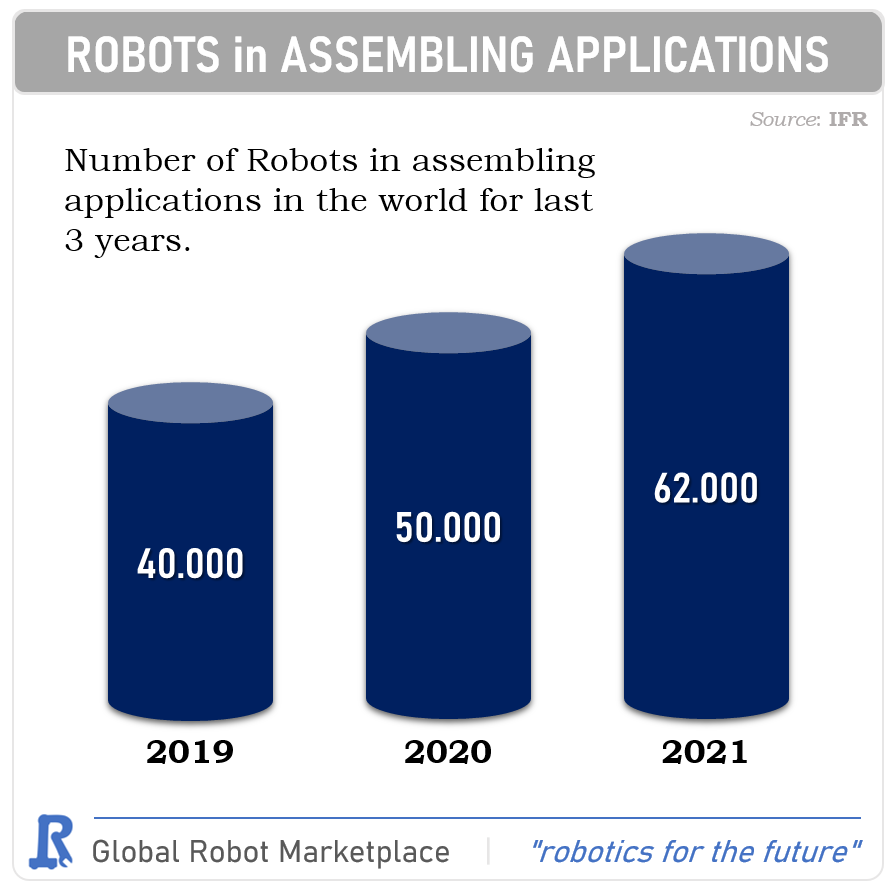

Industrial Robot Usage in Assembling Applications in the World for Last 3 Years:

The use of robots in assembly applications can also help to reduce costs. While the initial investment in robotic technology may be expensive, the long-term savings can be significant. Robots are able to perform tasks without the need for human intervention, which can help to reduce labor costs. Robots are also able to work faster and more efficiently, which can lead to faster production times and lower costs.

There are several different types of robots used in the assembly process, including cartesian robots, SCARA robots, and articulated robots. Cartesian robots are used for tasks that require linear movements, such as pick and place applications. SCARA robots are used for tasks that require a high degree of accuracy, such as assembly and packaging. Articulated robots are used for tasks that require a high degree of flexibility, such as welding and painting.

In conclusion, the use of robots in assembling applications offers many advantages, including increased efficiency, improved quality, and reduced costs. With advancements in technology and automation, the use of robots in the assembly process is expected to continue to grow in popularity. As companies look for ways to improve their manufacturing processes, the use of robotic technology is likely to become an increasingly important tool in their arsenal.

Global Robot Marketplace